A Year in Awe

Banff, AB. FOW: Matt Sterbenz // Photo: Carson Meyer (@carsonmeyerphoto)

Banff, AB. FOW: Matt Sterbenz // Photo: Carson Meyer (@carsonmeyerphoto)

This time last year, these skis did not exist. With the combined efforts of Checkerspot’s scientists, our engineers in Salt Lake City, and a growing number of FOWs around the world, we have come a long way in short order.

As we set off for another lap towards a brighter, more thoughtful 2020, here’s a brief look back at the milestones that got us here.

January/February

- The Algal Composite Core. We begin testing materials from the Checkerspot technology platform that will become instrumental to the core of our ski. We iterate upon dozens of chemical formulations until we find a composition optimal for integration into a ski design.

- Our first prototype was born. We begin pressing and testing the ski’s design and composition.

Raw form composites for cores awaiting resaw, laminating and profiling. Salt Lake City, UT. Photo: Carson Meyer (@carsonmeyerphoto)

Raw form composites for cores awaiting resaw, laminating and profiling. Salt Lake City, UT. Photo: Carson Meyer (@carsonmeyerphoto)

March/April

- Full ski lab testing. Equipped with a unique ski testing machine developed by engineers at Sherbrooke University, we are able to quantitatively test our full ski prototypes against other skis and gain a better understanding of how the integration of new materials affects complete ski performance.

Just a little more in depth than the old hand-flex test. Mechanical engineer and Director of MFG, Daniel Malmrose, evaluates a prototype Intention 110. Salt Lake City, UT. Photo: Carson Meyer (@carsonmeyerphoto)

Just a little more in depth than the old hand-flex test. Mechanical engineer and Director of MFG, Daniel Malmrose, evaluates a prototype Intention 110. Salt Lake City, UT. Photo: Carson Meyer (@carsonmeyerphoto)

- The ultimate road trip. Matt Sterbenz and a crew of guides, local legends, and backcountry veterans hit the road to put our prototypes to the test in the wild, covering hundreds of miles and thousands of vertical feet across the Wasatch, Bridgers, Tetons, and Rogers Pass with photographer Carson Meyer.

Where the road ends, the fun begins. FOW: Matt Sterbenz, Joey Weamer and Dan Gish // Photo: Carson Meyer (@carsonmeyerphoto)

Where the road ends, the fun begins. FOW: Matt Sterbenz, Joey Weamer and Dan Gish // Photo: Carson Meyer (@carsonmeyerphoto)

- WNDR Alpine website. We develop our digital presentation in preparation for launch showcasing our facility and photos from the road showcasing the product in action. As a consumer-direct brand, our mission is to provide turn key environmentally conscious solutions to get our skis on snow as fast as possible, leading to complimentary binding mounting, skin trimming, reusable packaging, carbon neutral free delivery and a hassle-free “Love it or Return it” policy.

May/June

- Final test laps in the Northern Hemisphere. 2019’s near record breaking season gives us ample time to continue testing our prototypes in variable Spring conditions.

- The Intention 110. We lock in on the final design for our first model and start laying the groundwork for production. The Intention 110 name takes shape as an ode to the philosophy of designing products with intention to produce quality, performance driven products built using more environmentally friendly processes, down to the chemistry of our materials.

- Full production. Our team in SLC goes into full-production mode in preparation for launch.

July/August

- WNDR Alpine goes live! On July 8th, we go live to the world and the Intention 110 becomes the first ski to incorporate biotechnology with its Algal Composite Core.

At last, the Intention 110 is unveiled to the world! San Juan Range, CO. FOW: Xan Marshland // Photo: Liz Forster

At last, the Intention 110 is unveiled to the world! San Juan Range, CO. FOW: Xan Marshland // Photo: Liz Forster

September/October

- Pep Fujas joins WNDR Alpine. We welcome Pep Fujas to our team as our VP of Marketing and Product Development.

Welcome aboard, Pep! Salt Lake City, UT. FOWs: Matt Sterbenz and Pep Fujas // Photo: Carson Meyer (@carsonmeyerphoto)

Welcome aboard, Pep! Salt Lake City, UT. FOWs: Matt Sterbenz and Pep Fujas // Photo: Carson Meyer (@carsonmeyerphoto)

- FOWs join the crew. As the word spreads, our Friends of WNDR grow in number. We find ourselves in the company of like minded athletes and backcountry explorers across North America as the temperatures drop and the snow starts to fly.

- The Blister Podcast. Matt Sterbenz and Xan Marshland join Jonathan Ellsworth on Blister’s Gear:30 podcast, discussing the development of the Intention 110 and our backstory.

- First Pairs of Preorders Ship. We take extra care to eliminate as much single-use plastic as we can in the shipping process, by foregoing shrink wrap and instead wrapping skis in recycled paper, using repulpable tape, and shipping in a reusable Dakine x WNDR travel bag.

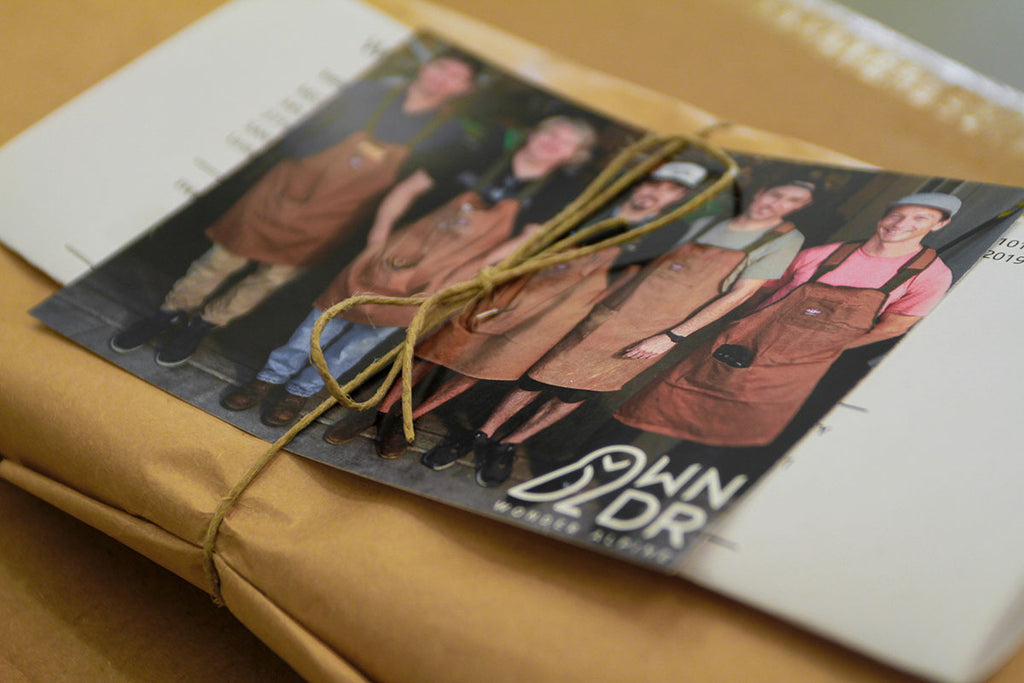

Shipped UPS Carbon Neutral. With love, from WNDR Alpine. Salt Lake City, UT. Photo: Pep Fujas (@pepfujas)

Shipped UPS Carbon Neutral. With love, from WNDR Alpine. Salt Lake City, UT. Photo: Pep Fujas (@pepfujas)

- Southern hemisphere shakedown. FOW Harrison Brickman takes the first pair of 192cm reverse camber Intention 110s off the press to Chile for some aggressive on-snow testing in Patagonia. The conditions were across the board, from wind packed, crud, sastrugi, to a few days of 3-7cm of dense fluff on the aforementioned. After the trip, the ski comes back to the Design Lab for testing and shows no evidence of changes in performance characteristics and 192s launch into production.

November/December

- Ascendance. Level1 produces a short film for us called Ascendance, a celebration of the early season transition from ski building to skiing in the Wasatch.

- The stoke spreads. We begin to get initial on-snow impressions on the Intention 110 from our earliest adopters. Read some of their reactions here, and stay tuned for more reviews coming shortly!

- We sell out of the reverse camber 185. As a testament to our early adopters’ love of the Intention 110, our most popular size/camber configuration sells out. We may have under-forecasted, so we decided to press another 25 prs and those sold out too.

- A new technology story takes shape. To be announced later this year...

In sum, we couldn’t be more grateful to our extended WNDR team, for you, the skiers we serve, and for the privilege to make better performing backcountry tools. And of course, we’re grateful for nature - for its ability to bring us awe, challenge us, and inspire new innovations.

From all of us at WNDR Alpine, have a safe and happy 2020!

PS: It’s not too late to start the new year off right with the most balanced and intuitive backcountry skis in the world! Be sure to check out our kits and deals on accessories.